Lean Management Research Center of Tianjin University of Science and Technology

Lean Management Research Center of Tianjin University of Science and Technology

I. Background of Establishment and Relying Platform

The Lean Management Research Center of Tianjin University of Science and Technology is a research institution integrating industry, academia and research, established based on the multi-disciplinary advantages of the university. It is dedicated to combining lean management theories with modern industrial technologies. In 2023, it was approved to build a characteristic discipline group of lean and intelligent management for the light industry in Tianjin. It serves the transformation and upgrading of enterprises and the economic development of society.

This center is deeply integrated into the "light industry characteristics" educational orientation of Tianjin University of Science and Technology. It is supported by disciplines such as industrial engineering and management science and engineering and integrates resources from multiple fields including the School of Economics and Management, the School of Food Science and Engineering, and the School of Biological Engineering to form a cross-disciplinary research team. Its establishment is closely related to the university's long-standing educational philosophy of "highly aligning classroom teaching with the needs of enterprises", aiming to promote the bidirectional drive of professional teaching reform and enterprise practical demands through industry-university-research cooperation.

II. Research Directions and Core Areas

1. Lean Production and Process Optimization

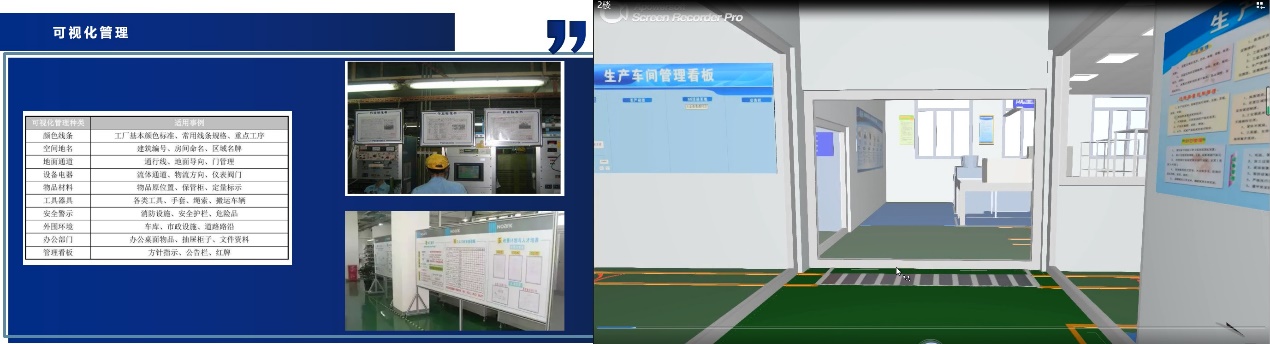

The research center focuses on enhancing enterprise production efficiency and reducing waste through lean management methods such as 6S management, SOP (Standard Operating Procedure) compilation, and factory layout optimization. Typical cases include optimizing the workshop flow line planning for Guishunzhai Food Company and introducing digital modeling and simulation technology to design the optimal production layout.

2. Digital and intelligent integration innovation

By integrating intelligent manufacturing technologies (the integration of lean, digital and automated manufacturing), traditional enterprises are driven to transform into intelligent ones. For instance, mathematical modeling software can be utilized to simulate the production process, addressing issues related to the compatibility of equipment layout and new product processes.

3. Supply Chain and Brand Management

It extends to areas such as brand design and promotion, logistics route planning, etc., assisting enterprises in building a full-chain management system from production to the market.

4. Cross-industry application expansion

The research fields cover multiple industries such as food, medicine, environmental protection, and military industry. It has provided consulting services for over a hundred enterprises in fields like electronics, agriculture and animal husbandry, and medical devices.

III. Key Members and Academic Resources Core team:

Mao WenJuan (Director of the International Exchange Department): Responsible for the management of industry-university-research cooperation projects, leading the university-enterprise docking and resource integration.

Zheng Hui (Director of the Department of Industrial Engineering and Head of the Research Center): Promote the integration of practical industrial engineering with lean management techniques, emphasizing the alignment of classroom teaching with the demands of enterprises.

Chen Gang and Wei Bo: Focused on on-site management improvement projects, leading the optimization of factory layout and the design of standardized processes.

Interdisciplinary collaboration: The team integrates management experts from the School of Economics and Management, technical R&D personnel from the School of Food Science and Technology, and process experts from the School of Biological Engineering, forming a multi-disciplinary research model.

Research support: Relying on 34 provincial and ministerial-level or higher research platforms of the university (such as the State Key Discipline of Food Science and Engineering), and in combination with the construction of the national first-class discipline of industrial engineering, theoretical and technical guarantees are provided for research.

IV. Representative Cooperative Projects and Achievements

1. Guishunzhai Lean Management Project

Achievements: Through the optimization of workshop layout, the standardization of SOPs and the introduction of 6S management, the production efficiency of the enterprise has been increased by over 30%, costs have been reduced by 40%, and the annual value-added benefit is approximately 8.6 million yuan.

2. Technological Innovation: For the first time in the food industry, modeling and simulation software are adopted to simulate the dynamic production environment.

3. Industry service extension

We have provided management consulting services for large enterprises such as Tianjin Food Group, Bohai Securities, and Offshore Oil Engineering, covering areas such as state-owned enterprise reform and intelligent factory construction.

During the "14th Five-Year Plan" period, I participated in the cultivation of provincial and ministerial-level scientific research projects, such as "Technology for the Supply Chain of Fresh Food Products", and promoted the transformation of scientific research achievements.

4. Academic Activities and Influence

Host or co-host academic conferences such as the "Artificial Intelligence and Lean Digital Management Innovation Symposium" to explore the integration path of new quality productivity and lean management. Promote knowledge sharing between the academic and industrial sectors through activities like the "Research and Knowledge Mutual Assistance" academic salon.

V. Social Contributions and Development Vision

The research center, with the mission of "serving the national economy and people's livelihood", contributes to social development through the following paths:

1. Enterprise Empowerment: Assist time-honored brands in breaking through traditional management bottlenecks and achieving "upholding tradition while innovating" (such as the case of Gui Shun Zhai); support small and medium-sized enterprises in establishing lean management systems.

2. Talent cultivation: Through joint school-enterprise projects, we cultivate industrial engineering professionals, and our employment rate consistently ranks among the top in similar majors.

3. Policy Support: Participate in the research of Tianjin's digital industrialization innovation policies and promote regional industrial upgrading.

In the future, the center will continue to deepen the integration of lean management with technologies such as artificial intelligence and big data, explore the intelligent transformation paths for characteristic industries like light industry and food, and contribute to the construction of "Double First-Class" universities and the country's high-quality development strategy.

Address of the Research Center: Room 405, Building 16, Tianjin University of Science and Technology, No. 1038, Daguhu South Road, Hexi District, Tianjin City.

Contact person: Zheng Hui

Email: tjzhenghui@tust.edu.cn